Introduction | Reliable Aluminum Extrusion Supplier

China dominates global aluminum extrusion production, accounting for over 50% of the world’s output. However, the market is saturated with manufacturers of varying quality, making it critical to choose partners wisely.

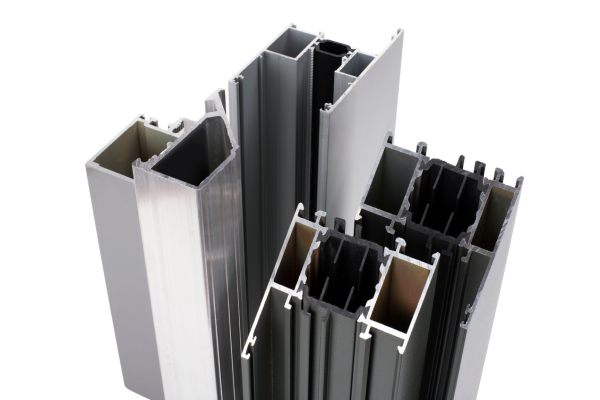

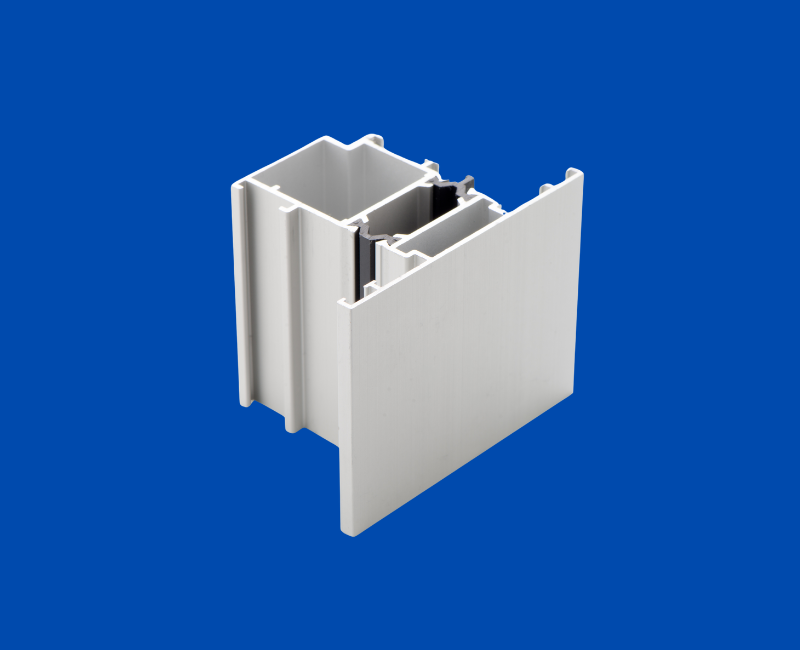

Custom aluminum extrusions are essential in industries like construction, automotive(e.g., enclosure), renewable energy (e.g., solar racking), and industrial machinery. Selecting reliable manufacturers directly impacts product quality, delivery timelines, and cost efficiency.

We can provides actionable strategies for evaluating technical capabilities, verifying credentials, and mitigating risks, supported by detailed comparison tables and tools.

Selecting a reliable custom aluminum extrusion manufacturer requires a holistic evaluation of multiple dimensions, balancing technical capabilities with soft skills. While scale is foundational, it’s not about blindly chasing "bigger is better." Large-scale factories often boast advanced equipment (e.g., CNC machining centers, aging furnaces) and stable production for standardized, high-volume orders.

However, smaller or mid-sized enterprises may excel in flexibility and personalized service, particularly for complex designs or small-batch needs. Assess their equipment quality (e.g., precision CNC machines), workforce stability (long-term technical teams), and past project portfolios to gauge alignment with your requirements.

Design capabilities are pivotal for turning concepts into feasible products. A reliable manufacturer should transcend mere "manufacturing from drawings" and proactively optimize designs. For instance, they might use Finite Element Analysis (FEA) to validate structural integrity, propose weight reduction strategies, or enhance thermal performance. Collaborative 3D modeling and iterative prototyping are also critical.

Production capacity directly impacts delivery timelines. Beyond raw metrics like monthly output or machine count, scrutinize actual utilization rates and production flexibility.

Ask for some question? like, Can they accommodate urgent orders via overtime or multi-factory coordination? Is their raw material supply chain (e.g., aluminum billet procurement) resilient? What about logistics efficiency? Ask for detailed production schedules and assess whether timelines are realistic. Contingency plans, such as backup suppliers or distributed manufacturing networks, are worth exploring to mitigate bottlenecks.

Certifications serve as non-negotiable benchmarks for quality and compliance. Industry-specific requirements vary: automotive sectors demand IATF 16949, aerospace requires NADCAP certification, while exports to the EU necessitate RoHS and REACH compliance. Verify that certifications align with your industry and request original documents or official verification channels. However, certifications alone aren’t sufficient—observe their quality control practices firsthand. Are inspections systematic (e.g., spectral analysis, tensile testing)? Do they deploy automated tools like CMMs (Coordinate Measuring Machines)? A robust traceability system is equally vital.

Industry experience acts as a facilitator that minimizes communication barriers. Seasoned manufacturers deeply understand sector-specific nuances: lightweight, corrosion-resistant alloys for renewable energy applications; weather-resistant finishes for architectural projects; or stringent tolerances for electronics. Review their case studies for comparable projects and engage existing clients for candid feedback. For custom orders, request process flowcharts or quality control documentation to evaluate their grasp of industry pain points.

Additional yet critical factors include:

- Cost transparency: Does the quote include mold design, surface treatment, logistics, or hidden fees?

- Geographic proximity: Will domestic or overseas suppliers impact lead times or tariffs?

- Sustainability practices: Do they comply with ESG standards, such as eco-friendly wastewater treatment or recycling programs?

The following standards that can be offered for reference

Technical Standards——Core Evaluation from Material to Process

1. Material Performance:The Foundation of Aluminum Extrusions

Key Testing Metrics

Technical Insights:

- Anodizing: Film thickness determines corrosion resistance. Architectural applications require ≥15μm, while industrial use demands ≥25μm.

- Extrusion Precision: Check straightness (GB 5237.1 standard: ≤1.5mm/m deviation over the entire length).

2. Processing Technology: Drivers of Precision

Critical Evaluation Criteria

-

Die Design and Manufacturing

- Material: H13 steel for high-temperature durability.

- Nitriding Hardness: ≥HV 1000 for extended die life.

- Texture Alignment: Ensure die design matches required grain direction (provide cross-sectional diagrams).

-

Heat Treatment Processes

- Solution Treatment: Temperature maintained at 530±5°C.

- Aging: Natural cooling for 48 hours (T5 temper).

- Documentation: Require heat treatment certificates (e.g., T6/T5 status labels).

-

Surface Finishing Techniques

- Wood Grain Transfer: Test adhesion using ASTM D4541 pull-off tests.

- Fluorocarbon Coating: Film thickness ≥40μm compliant with AAMA 2605 standards.

3. Quality Certifications: Mandatory Compliance

| Certification | Applicability | Verification Steps |

|---|---|---|

| ISO 9001 | Global quality management baseline | Verify via SGS/SGS.org certificate portal |

| ASTM B221 | North American market compliance | Check certificate validity period (typically 3 years) |

| RoHS | EU market (heavy metal restrictions) | Third-party lab reports (SGS/BV) |

| GB/T 6892-2015 | Domestic architectural standards | Confirm standard number on product tags |

Red Flags:

- Fake Certifications: Use official databases (e.g., SGS website) to validate certificates.

- Expired Certifications: Require renewal timelines during contract negotiations.

Credential Verification: 6 Essential Documents to Audit

1. Mandatory Documentation Checklist

Risk Mitigation——From Factory Audits to Contract Clauses

1. Factory Audit Checklist

2. Contract Clauses to Prevent Disputes

Essential Attachments:

- Technical specifications (tolerances, surface finish codes).

- Payment milestones (e.g., 30% deposit + 40% progress payments + 30% upon acceptance).

- Warranty terms (e.g., 5-year structural warranty with corrosion failure coverage).

Supplier Comparison——Case Studies of 3 Manufacturers

Risk Assessment Methodology: Evaluated across 5 categories: technical capabilities, financial stability, compliance history, scalability, and client reviews.

Finally, validate capabilities through a pilot order. Small-batch trials reveal responsiveness, problem-solving agility, and service attitude. Long-term partnerships should evolve into strategic collaborations, blending technical synergy with mutual growth. Ultimately, the ideal manufacturer is not just a transactional vendor but a partner invested in your success.please send us a inquiry if you have any confusion about your procument plan.