China's Top Aluminum Manufacturers and Suppliers: A Sourcing Guide 2025

China is a global leader in aluminum production, with many manufacturers excelling in quality, innovation, and customer service. From architectural applications to industrial and automotive components, Chinese aluminum suppliers have cemented their reputation worldwide. In this blog, we highlight some of the top manufacturers in the industry, including Fenglu Aluminium Industries, Xingfa Aluminium, JMA Manufacturing, and others, showcasing their strengths, weaknesses, and certifications.

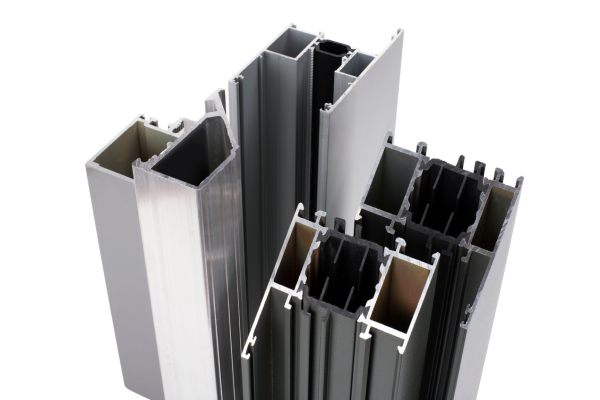

1.Fenglu Aluminium Industries

Established: 1990 | Location: Foshan, Guangdong Province, China

Main Products: Aluminum Sheets, Aluminum Profiles, Aluminum Extrusions, Aluminum Plates

Company Profile: Fenglu Aluminium Industries is a seasoned manufacturer with over 20 years of experience. They specialize in producing high-quality aluminum products for both industrial and commercial applications.

Advantages:

- State-of-the-art production facilities.

- Competitive pricing.

- Extensive product range.

- Excellent customer service.

Disadvantages: - Higher minimum order quantities (MOQs) for specialized products.

Certifications: ISO9001, ISO14001, IATF16949, AS9100.

Fenglu is a reliable choice for businesses seeking durable and customizable aluminum solutions.

2.Xingfa Aluminium

Established: 1984 | Location: Foshan, Guangdong Province, China

Established: 1984 | Location: Foshan, Guangdong Province, China

Main Products: Aluminum Profiles, Curtain Wall Systems, Industrial Aluminum Products

Company Profile: Xingfa Aluminium is a pioneer in architectural aluminum systems and industrial applications. Their products are widely used in construction, transportation, and industrial sectors.

- Advantages:

Advanced extrusion technology.

Comprehensive product line.

Strong R&D capabilities.

- Disadvantages:

Extended delivery times for customized solutions.

- Certifications: ISO9001, ISO14001, CE, Qualicoat.

Xingfa is a go-to supplier for architectural and industrial aluminum needs.

3.JMA Aluminum

Established: 1994 | Location: Foshan, Jiangsu Province, China

Established: 1994 | Location: Foshan, Jiangsu Province, China

Main Products: Custom Aluminum Extrusions, Architectural Systems, Industrial Components

Company Profile: JMA Manufacturing specializes in precision aluminum extrusions and fabrication services, offering end-to-end solutions for industries like construction, automotive, and electronics.

Advantages:

- Custom design capabilities.

- High precision manufacturing.

- Integrated solutions.

Disadvantages: - Longer lead times for complex custom projects.

Certifications: ISO9001, ISO14001, OHSAS18001.

JMA is ideal for businesses requiring tailored aluminum solutions.

4.Nanshan Aluminum

Established: 1993 | Location: Longkou, Shandong Province, China

Established: 1993 | Location: Longkou, Shandong Province, China

Main Products: High-end Aluminum Products, Aviation Materials, Automotive Components

Company Profile: Nanshan Aluminum is a leader in high-performance aluminum products, focusing on aviation, automotive, and marine applications.

Advantages:

- Advanced technology.

- High-quality standards.

- Strong research capabilities.

Disadvantages: - Premium pricing for specialized products.

Certifications: AS9100, IATF16949, ISO9001, NADCAP.

Nanshan is a trusted partner for critical industries.

5.Weiye Aluminum Factory

Established: 1992 | Location: Foshan, Guangdong Province, China

Established: 1992 | Location: Foshan, Guangdong Province, China

Main Products: Construction Aluminum Profiles, Industrial Aluminum Systems

Company Profile: Weiye Aluminum Factory specializes in aluminum profiles for construction and industrial applications, offering innovative designs.

Advantages:

- Cost-effective solutions.

- Quick delivery.

- Flexible production capabilities.

Disadvantages: - Limited customization options for small orders.

Certifications: ISO9001, CE, RoHS.

Weiye is a practical choice for budget-conscious buyers.

6.Huachang Group

Established: 1992 | Location: Foshan, Guangdong Province, China

Established: 1992 | Location: Foshan, Guangdong Province, China

Main Products: Aluminum Building Materials, Decorative Profiles, Industrial Components

Company Profile: Huachang Group offers a comprehensive range of aluminum solutions, specializing in architectural and industrial applications.

Advantages:

- Diverse product range.

- Technical support.

- Quality assurance.

Disadvantages: - Higher MOQs for custom finishes.

Certifications: ISO9001, ISO14001, CE.

Huachang is a reliable partner for architectural and industrial projects.

7.Liangyin Aluminum

Established: 2009 | Location: Foshan, Guangdong Province, China

Established: 2009 | Location: Foshan, Guangdong Province, China

Main Products: Industrial Aluminum Profiles, Heat Sinks, Precision Components

Company Profile: Liangyin Aluminum focuses on high-precision aluminum components, particularly for thermal management and custom extrusions.

Advantages:

- High precision manufacturing.

- Specialized solutions.

- Technical expertise.

Disadvantages: - Higher costs for small batch production.

Certifications: ISO9001, ISO14001, TS16949.

Liangyin is perfect for businesses needing precision-engineered aluminum parts.

8.Jinqiao Aluminium Industry

Established: 1983 | Location: Hong Kong, Guangdong Province, China

Established: 1983 | Location: Hong Kong, Guangdong Province, China

Main Products: Aluminum Profiles, Industrial Components, Architectural Systems

Company Profile: Jinqiao Aluminium Industry offers a wide range of products for construction, industrial, and transportation sectors, emphasizing quality and innovation.

Advantages:

- Diverse product portfolio.

- Quality control systems.

- Professional service.

Disadvantages: - Longer processing time for special specifications.

Certifications: ISO9001, ISO14001, OHSAS18001.

Jinqiao is a versatile supplier for various industries.

Why Choose Chinese Aluminum Manufacturers?

- Global Reputation: Chinese aluminum manufacturers are trusted worldwide for their quality and reliability.

- Diverse Product Range: From standard profiles to custom extrusions, these companies offer tailored solutions.

- Certifications: Most manufacturers adhere to international standards, ensuring compliance and quality.

- Competitive Pricing: Despite high-quality standards, many offer competitive pricing.

How to Choose the Right Aluminum Alloy?

Selecting the appropriate aluminum alloy for a specific application is a critical decision that requires careful consideration of multiple factors. This article will guide you through the process of choosing the right aluminum alloy by examining three key aspects: strength, corrosion resistance, and cost.

Understanding Aluminum Alloys

Aluminum alloys are classified into different series based on their primary alloying elements. The most commonly used series include:

- 1xxx Series: Pure aluminum with high electrical and thermal conductivity, excellent corrosion resistance, and formability. However, it has relatively low strength.

- 2xxx Series: Aluminum-copper alloys known for their high strength, especially in the heat-treated condition. They are widely used in aerospace applications but have lower corrosion resistance compared to other series.

- 3xxx Series: Aluminum-manganese alloys with good corrosion resistance, moderate strength, and excellent formability. They are commonly used in beverage cans and architectural applications.

- 4xxx Series: Aluminum-silicon alloys often used as welding wire or in castings. They have good fluidity and corrosion resistance.

- 5xxx Series: Aluminum-magnesium alloys offering a good balance of strength, corrosion resistance, and weldability. They are widely used in marine, transportation, and construction industries.

- 6xxx Series: Aluminum-magnesium-silicon alloys with good strength, corrosion resistance, and formability. They are commonly used in architectural extrusions, automotive parts, and consumer products.

- 7xxx Series: Aluminum-zinc alloys known for their high strength, especially in the heat-treated condition. They are widely used in aerospace and high-performance applications but require proper corrosion protection.

Balancing Strength

The required strength of an aluminum alloy depends on the specific application. For example, in aerospace and automotive industries, high-strength alloys are needed to withstand heavy loads and impacts. In contrast, architectural applications may require moderate strength combined with good formability and corrosion resistance.The strength of an aluminum alloy is typically measured by its yield strength, tensile strength, and elongation. Yield strength is the stress at which a material begins to deform plastically, while tensile strength is the maximum stress a material can withstand before breaking. Elongation measures the material's ability to stretch before breaking.

Selecting Alloys Based on Strength

- High-Strength Applications: For applications requiring high strength, such as aerospace and automotive structural components, the 2xxx and 7xxx series alloys are commonly used. These alloys can achieve high strength through heat treatment processes such as solution heat treatment and aging.

- Moderate-Strength Applications: For applications where moderate strength is sufficient, such as architectural extrusions and consumer products, the 6xxx series alloys are a good choice. They offer a good balance of strength, corrosion resistance, and formability.

- Low-Strength Applications: For applications where low strength is acceptable, such as beverage cans and some decorative items, the 1xxx and 3xxx series alloys can be used. These alloys are relatively soft but have excellent corrosion resistance and formability.

Aluminum is naturally resistant to corrosion due to the formation of a thin, protective oxide layer on its surface. However, this layer can be damaged by various factors such as exposure to harsh chemicals, moisture, and mechanical abrasion, leading to corrosion.Some Factors Affecting Corrosion Resistance,like:

- Alloy Composition: The presence of certain alloying elements can affect the corrosion resistance of aluminum alloys. For example, copper and iron can reduce corrosion resistance, while magnesium and manganese can improve it.

- Surface Finish: The surface finish of an aluminum product can also affect its corrosion resistance. A smooth, polished surface is less prone to corrosion than a rough or porous surface.

- Environmental Conditions: The environment in which the aluminum product is used can have a significant impact on its corrosion resistance. For example, exposure to saltwater, acidic or alkaline solutions, and high humidity can accelerate corrosion.

Selecting Alloys Based on Corrosion Resistance

- High-Corrosion Environments: For applications in high-corrosion environments, such as marine and chemical processing industries, the 5xxx series alloys are a good choice. They contain magnesium, which forms a stable oxide layer that provides excellent corrosion resistance. Additionally, some 6xxx series alloys with high magnesium content can also offer good corrosion resistance.

- Moderate-Corrosion Environments: For applications in moderate-corrosion environments, such as architectural and automotive applications, a wide range of aluminum alloys can be used. The 6xxx series alloys are popular due to their good balance of strength, corrosion resistance, and formability. The 3xxx series alloys are also suitable for some architectural applications where moderate corrosion resistance is required.

- Low-Corrosion Environments: For applications in low-corrosion environments, such as indoor decorative items and some consumer products, the 1xxx series alloys can be used. They are pure aluminum with excellent corrosion resistance but relatively low strength.

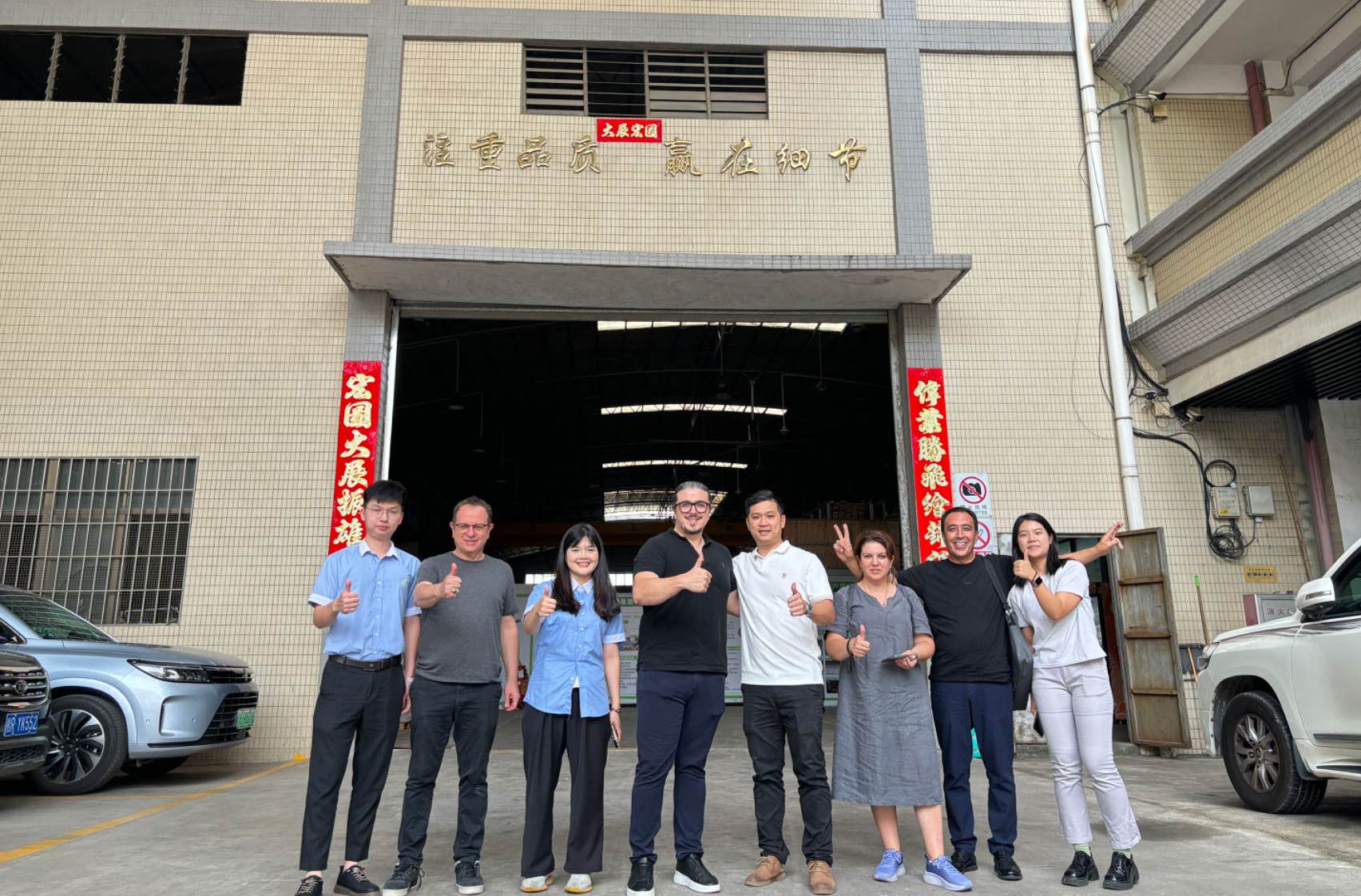

Ready to Source High-Quality Aluminum Products?

At GoodsSourcing, we specialize in connecting you with verified aluminum manufacturers in China. Our experienced team can help you:

• Find the most suitable manufacturer for your specific needs

• Ensure competitive pricing and quality standards

• Handle communication and negotiation

• Manage quality control and logistics

Save time and reduce risks in your sourcing journey.

Contact us today for a free consultation!

Contact us today for a free consultation!

Let our expertise guide your aluminum sourcing success in China.